Electrical Wiring and Safety in the Workplace

Introduction

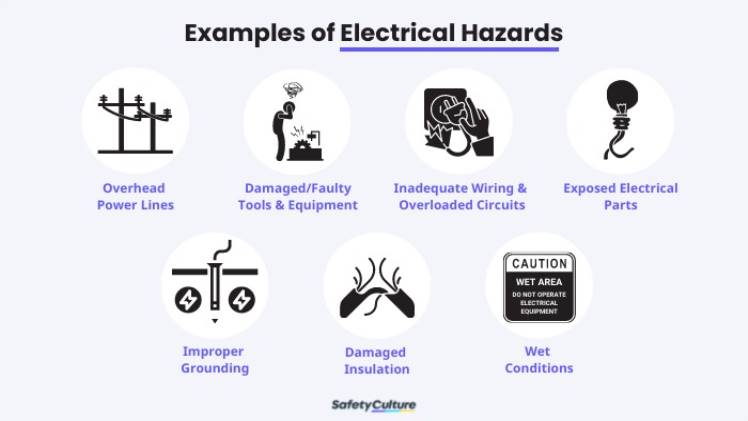

Electrical wiring and safety are paramount for the prevention of fires and electric shock. To ensure that employees are trained on and aware of the hazards associated with electricity, it’s essential that they receive appropriate training.

Any worker who comes in contact with a live conductor or circuit part can suffer an electric shock. A person who receives such damage to their heart, lungs, internal organs and muscles could be permanently disabled.

Protective materials used in the workplace must be insulated for the voltage of a circuit and protected from damage. If tools or equipment are not insulated, the insulation must be removed or replaced with nonconductive material. If these may come into contact with exposed energized conductors or circuit parts, they must be equipped with insulating materials and an attendant stationed to warn employees and provide protection.

Insulating materials must be nonconductive, and tools or equipment tested to eliminate electric shock hazards. Employees must wear protective gloves and insulated-soled shoes when handling equipment that could come into contact with exposed energized components or conductors.

Working in damp or wet environments can lead to electrical shock injuries. Water can turn substances that act as insulators into conductors or even better conductors, so it’s essential for workers to keep work areas dry and use dry hand wipes for cleaning tasks.

It’s essential to ensure the work area is cooled off both during and after working with electrical equipment. Doing so prevents heat damage to equipment, as well as reduces the likelihood of arcing which could result in electric shock.

Employees must wear gloves or insulated shoes and have the equipment they are working with inspected prior to working with it. The testing should ensure that the equipment meets all necessary wattages before usage.

When workers must work near energized conductors or circuit parts, an attendant should be available to warn and protect employees when signs and barricades fail to do so. Alternatively, protective shields or barriers must be used to shield employees from coming into contact with un-insulated energized conductors or circuit parts.

Occupational health professionals should be available to offer training and education for employees who may come into contact with energized parts, as well as follow-up instruction in case of an electrical injury. An attendant should also be on-hand to administer first aid and CPR when needed.

An energized wire is a potential safety hazard that should be immediately reported to your local utility company. Avoid getting close to an energized wire as doing so could result in burns.

It’s essential that your home is adequately insulated and any combustibles kept away from energized wires. According to the National Fire Protection Association (NFPA), a minimum distance of 20 feet should be kept between workers and an energized wire.

The International Electrotechnical Commission (IEC) produces codes and regulations that specify the voltage, current, functional specifications for wiring installations as well as related circuit protection, control and distribution devices. While the IEC strives to harmonize wiring standards among member countries, significant variations remain in design and installation requirements.

By visiting Advertisementpro and fmmagazines you can get more knowledge about multiple topics.